Before you get to the exciting part, you’ll need a few basic details about your system.

Here are some good questions about the correct sizing for an expansion tank from a for the conscientious installer — which I know includes all of us.

Question 1: Fill pressure vs. expansion tank size? (Or in other words, what should the loop pressure be and how much pressure should be in the expansion tank?)

Question 2: Expansion tank size vs. system fluid volume/ number of collectors? (Or, how to size the expansion tank to your solar system, including collectors, length of pipe, etc.)

Question 3: Fill pressure vs. PRVs? (How to size the pressure relief valve.)

Question 4: Fill pressure vs. head? (Does head or distance to the panel affect fill pressure?)

If you can visualize the concept of a correctly installed pressure glycol system, the answers will become more evident.

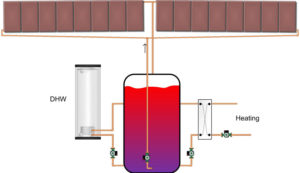

The goal is to keep the expansion tank from blowing off when the power fails on a super-hot day. To do this, the system needs to be designed along the lines of a drain-back system. (Sometimes it’s called a steam-back system.) This is the only sure way to design this to make it work correctly.

Let me explain, and your other questions will start to become clear once you understand how it works.

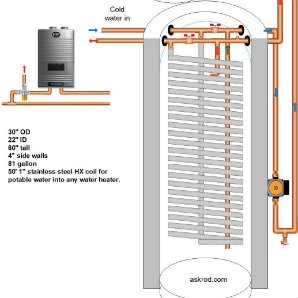

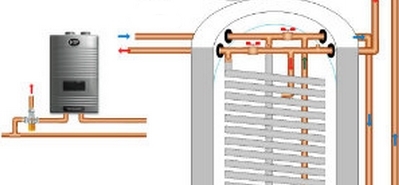

All plumbing coming out of the collector array MUST drop down several feet to form a thermal lock or trap for the steam in the collectors. The liquid/steam must not migrate at all. Water expands 1,130 times when it flashes. If in any way it can migrate and flow out of the collectors, it’s not possible to have a large enough expansion tank.

With this understanding, you can now start making the calculations you need. For example, a single 4’x10’ collector holds 1.3 gallons of water. So, if you have a string of eight 4’x10’ collectors, the water total is 10.4 gallons. This should have 1″ pipe (copper handbook). Never oversize the plumbing or you’ll lose control.

As the array heats and starts to flash, it will start to push the fluid back and DOWN the plumbing. Once it settles, the collectors now contain 10.4 gallons of steam volume, and about 10.4 gallons have been pushed down the plumbing into the expansion tank. Calculate expansion for the liquid in the plumbing (maybe 0 to 200°), and you now know what size the expansion tank needs to be. Or, I have an Excel spreadsheet I created years ago that will help you with the calculations. (Go to the “Sizing Tanks, Panels and WH” tab.)

Most systems have between 20 to 40 psi. Remember, every 100 feet of water has 44.4 psi. Add this to whatever you start with. Oh, and make sure you size the PRV with a good margin above set pressure.

The expansion tank should have a cold unloaded pressure set before you start to fill that is close to the psi your system will be set at. You cannot change or check the pressure on an expansion tank after it has been loaded because the reading won’t be accurate.

You might get some other suggestions for setting the pressure. I know Velux and Heliodyne have some interesting guidelines. Then too, I’m not a pro on pressure glycol systems. We do drain-back every chance we can. But, European collectors generally can’t do drain-back when they have a serpentine riser inside.

Good luck — or, do it correctly and you won’t need any luck!