Other posts have discussed light commercial systems for restaurants and other similar businesses. But what if you need a solar thermal system with a bit more uumph? Here’s the recipe for a solar hot water system that would be perfect for, say, apartment buildings or hotels. It provides 330 gallons of hot water per hour, […]

Read moreCommercial

I’m asked, more and more, to provide a solar hot water system design for light commercial systems. There is, indeed, an effective and simple design template for smaller commercial systems that need to heat up to 330 gallons of water per hour or less. The actual system this template is based on is for a […]

Read more

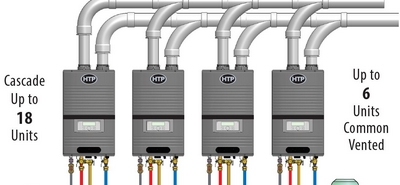

Here’s a new concept for commercial solar: a 250,000-Btu tankless water heater. It comes down to this simple philosophy: Don’t pay to heat ’til you need it. As you study this concept illustration, you’ll realize how simple this is. And, when you compare this setup to a conventional design, the cost will be half. back-up. […]

Read more

Out with the old (over complicated, expensive solar). In with the new (better and more efficient solar at lower cost). Case in point: the Minneapolis- St. Paul international Airport’s cutting-edge solar thermal system with a new innovative design approach. Two decades ago, conventional solar called for installing a water heater or, for larger systems, a […]

Read more